To leverage the unbeatable efficiency of the electric drivetrain, the entire vehicle structure must be tailored accordingly. That’s why the meticulously refined drivetrain system, designed to perfection down to the smallest detail, is at the core of our vehicles. It has been completely redesigned and customized for the TADUS tractor.

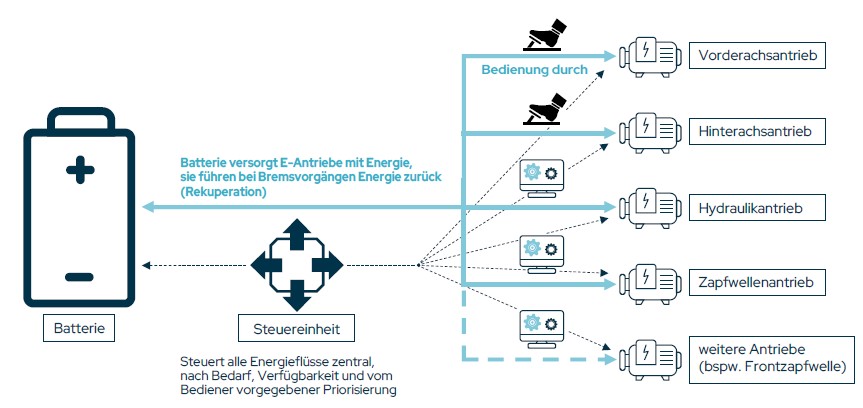

In the electric powertrain with multiple electric motors, the energy is transmitted as close as possible to each individual end consumer in the form of mechanical or hydraulic power. Each consumer is supplied individually and according to their specific needs. There is no mechanical coupling between the consumers, such as between the propulsion system and attachment. This results in significantly improved control and regulation, leading to a simpler and more intuitive operation.

The Advantages of the TADUS Propulsion System

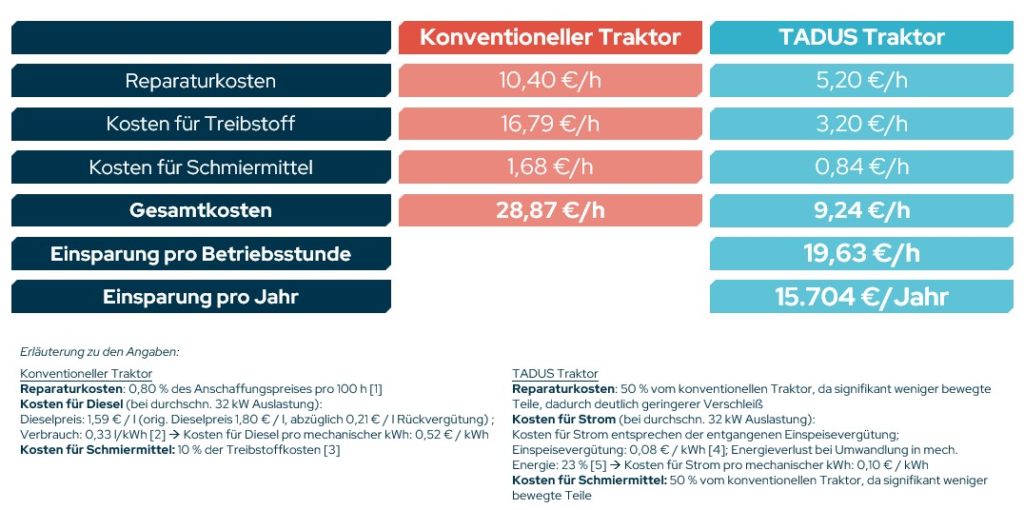

The greatest advantage: cost savings.

In addition to the numerous advantages in terms of driving performance, the TADUS tractor convinces primarily in economic terms: For farms with their own power generation, such as a photovoltaic system, according to our calculations and considering the current conditions, operating costs can be reduced by up to 70% compared to conventional tractors. But even if electricity is purchased, the anticipated savings are expected to be around 33%.

2nd Advantage: Independence.

Imagine consuming the electricity you generate on your own farm right there on the farm. You could achieve independence from the electricity market and diesel prices. The TADUS TRACTOR can be a crucial component in the farm’s self-sustaining energy cycle.

3rd Advantage: Extended Lifespan.

In a drivetrain with purely electric power transmission, significantly fewer moving parts are used compared to a drivetrain with mechanical power transmission. As a result, wear and tear in the TADUS TRACTOR is much lower than in a conventional tractor, and the lifespan can be extended by up to 50%.

4th Advantage: CO₂ savings.

The emission of pollutants is also significantly reduced with the TADUS tractor. When using self-generated PV electricity, the CO2 emissions even drop to 0. Considering the CO2 emissions of a conventional tractor under average load, a TADUS tractor supplied with self-generated electricity saves up to 525 tons of CO2 over its entire lifespan.

[co2sparen]

In the above calculation example, we consider an agricultural operation with its own PV system under the following assumptions: Tractor utilization: 800 hours/year; Rated power: 107 HP / 80 kW; Diesel consumption per hour: €13.21/h [9]; CO2 emissions per liter: 2.65 kg/l [10] –> CO2 emissions of the conventional tractor per hour: 34.98 kg/h.

Functionality of the Propulsion System

This design of the propulsion system optimally harnesses the unbeatable efficiency of the electric motors. Energy losses are minimized, resulting in lower maintenance and repair requirements, all while achieving a longer lifespan.

Sources:

- Maschinenkostenrechner Maschinenring Tirol

- ÖKL: Kraftstoffverbrauch in der Land- und Forstwirtschaft

- ÖKL: Berechnungsgrundlagen

- Presentation by TFZ on 23.01.2023 (Slides can be provided)

- Stiftung Energie und Klimaschutz

- CO2-Rechner von Quarks (Stand März 2023)

- CO2-Rechner von KlimAktiv (Stand März 2023)

- Destatis: Weltweiter CO2-Ausstoß 2021

- Dekra: Wissenscenter Umwelt und CO2